Introduction

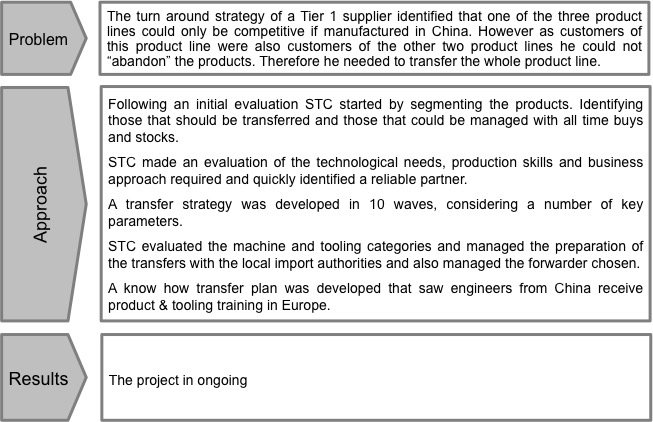

The complete transfer of an existing industrial activity, or part of a plant, product line or up-stream / down-stream operation is a major challenge. Choosing the right partner, managing the transfer, assuring the incident free start up are all major challenges in themselves.

STC manages such projects with the same rigour and standards as the “Supply Base Development” projects.

STC takes careful consideration of a whole host of factors, both short and long term. We consider a very large picture. The starting point is under-standing the client needs, which initially may be economic, however through the approach we take, STC extracts other important points to build a Business Specification. This is developed considering the evolution of time, and expands to cover subjects including; engineering, management, delivery & quality, particularly when we are talking about a product line that will continue to be developed.

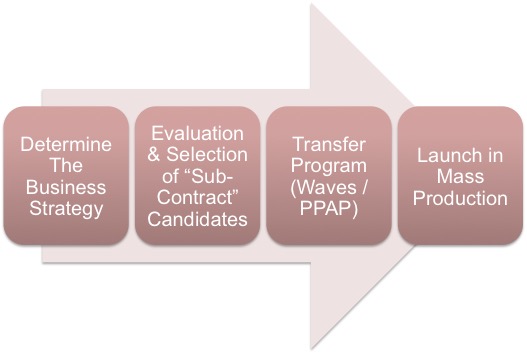

Once the “needs” are clear STC, leveraging either its databases or market research, works through a step-by-step program to; determine, evaluate and select the “Sub-Contractor”. Core to this work is our focus on their longer-term capability.

Process

STC organises the approach into several steps.

As opposed to a Resourcing or Dual Sourcing Project, an industrial transfer requires a far longer-term view and a real “Partnership Approach”.

Key points to consider include:

- What is the long term strategy for the concerned product line

- Will you need to work together with the partner for future developments

- Expectation of your customers

- Trust

- Capability to be trained and to learn

- Industrial Expertise

- …

Some of the key topics that would be addressed in an Industrial Transfer project include:

- Transfer Strategy

- Supply Agreement

- Project Management

- Transport & Customs

- Materials Management & Localisation

- Transfer of Know How

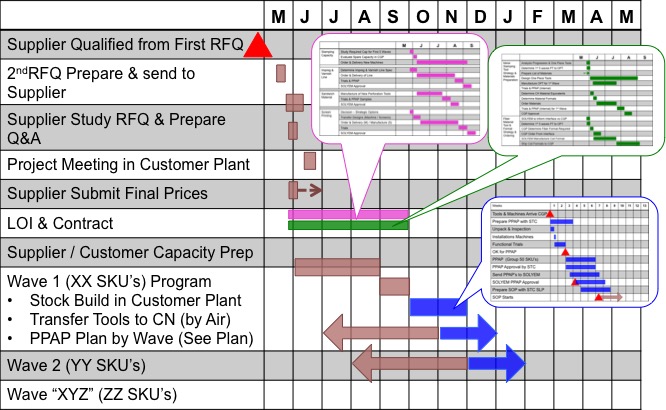

- PPAP & Safe Launch Plan

Transfer Strategy

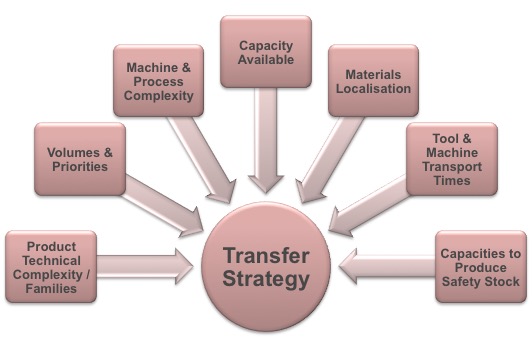

Once the Business Strategy in Clear and the Sub-Contract Partner selected a transfer strategy needs to be determined. Often such projects are complex with hundreds if not thousands of part numbers, and even more tools. Additional complexity comes as the projects include the transfer of machines and or the re-industrialisation with local technology.

STC develops for its clients a transfer strategy that considers a whole number of parameters:

Often we structure the transfer in waves which allows the transfer to be made in manageable steps allowing focus to be maintained and enabling an achievable safety stock strategy.

Supply Agreement

To support such complex projects a very well structured and detailed “Supply Agreement” is required. STC has over the years build a number of such Agreements and has developed a “Tool Box” of topics from which the customer and sub-contractor can select the relevant content and clauses.

These agreements can include topics such as:

- Pricing and Material Indexes and price point evolution

- Taxes

- Tooling Ownership

- Know How Ownership / Intellectual Property / Trademarks

- Machine Ownership

- Material Localisation Rules

- Productivity Sharing

- Forecasts, Order & Delievry

- Confidentiality

- Quality & Auditing

- Term & Termination

- Jurisdiction

- …

Project Management

Complex Industrial Transfers of this nature require a very proactive Project Management. Considering the rhythm of the transfer, the rate often at which the PPAP process needs to run, STC teams are present, on the ground, in the receiving sub-contractor plant every week. The tasks range from next wave planning through to witnessing tool / machine deliveries and process start up.

Further with locations in China and Europe STC teams can be in both the sending plant and receiving plant ensuring excellent communication and fine project coordination.

Transport & Customs

The choice of transportation, Air / Rail / Sea, is at first sight a balance between cost and lead-time. However STC takes a larger approach integrating factors such as: Longer lead-time means more safety stock that often carries a premium cost to manufacture. Faster time to production will bring the savings, associated with such projects, faster too.

Customs preparation is key. STC works closely with the authorities of the receiving country to prepare the files in order that once the tools, equipment and materials are delivered they quickly pass the necessary controls.

STC has further know how in the calculation of the value of second hand tools and equipment for the customs and a deep understanding of what can be really exported and accepted.

STC also has a strong experience in choosing and working with the forwarders for such complex transfers.

Materials Management & Localisation

The materials strategy is a key element in the industrial transfer. To maximise savings, bring simplification and avoid production delays, STC can build a materials localisation strategy. This strategy can be integrated into the transfer program and the PPAP program in order to avoid duplication of tasks.

STC can leverage its databases to find the materials / parts suppliers. Further it can help build a materials target pricing strategy to ensure that the benefits of the transfer project are maximised.

STC works with the suppliers to develop the necessary validation programs conducting back-to-back testing of the current and localised materials.

Transfer of Know How

STC builds a support program for the transfer to ensure the Know How required to manage the production is equally transferred. Starting from an audit STC identifies the key areas of know how within the processes, tooling, quality control. STC then builds programs of know how transfer that includes the exchange of staff during the preparation and physical transfer program. STC then audits the sub-contractor through the PPAP stage and start of mass production to ensure the thorough transfer.

PPAP & Safe Launch Plan

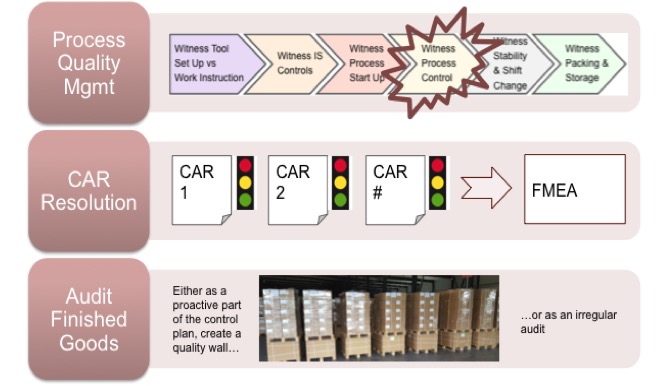

STC applies the same standards as used in its resourcing project to manage the PPAP and parts approval process. As mass production begins STC also employs its Safe Launch Plan.

Case Study