Introduction

In the development of a supply base STC takes careful consideration of a whole host of factors, both short and long term. We consider a very large picture. The starting point is under standing the client needs, which initially may be economic, however through the approach we take, STC extracts other important points to build a Resourcing Specification. This is developed considering the evolution of time, and expands to cover subjects including; engineering, management, delivery & quality. Also we consider aspects like geographical locations which in China can have an important impact.

Once the “needs” are clear STC, leveraging either its data-bases or market research, works through a step by step program to; determine, evaluate and select the supply base. Core to this work is our focus on the capability of the supplier and in particular his capacity to listen, learn and evolve.

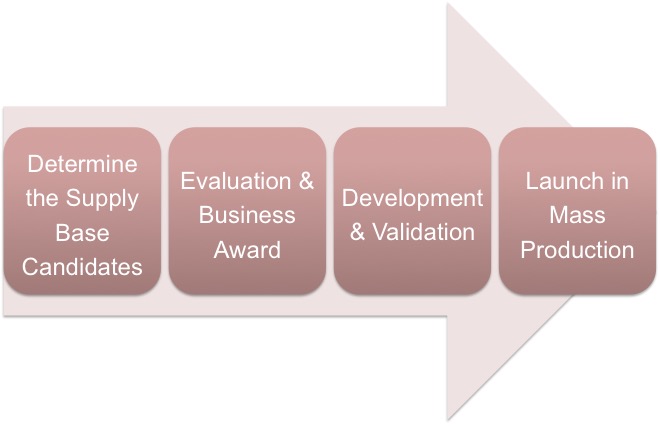

Process

STC organises the approach into several steps.

This structured method ensures that as the project progresses all the key objectives of each step are completed and approved by the client.

The solutions that STC brings will be designed in such a way to both manage risk, such as exchange rate or material index movements, as well as more fundamental risks and importantly enable the client to evolve the sourcing strategy over time.

To ensure that the timing of the program is respected STC will conduct a thorough preparation. This can include even the planning of critical machines in the tool manufacturing process.

During the course of the project STC has the expertise and experience to realise as well a number of contractual tasks, on behalf of the client, that include:

- Target Pricing developed from its deep understanding of the manufacturing processes,

- Price Negotiations,

- Inclusion of Material Indexes and price point evolution,

- Negotiation of Terms and Conditions,

- Drafting and Negotiation of Supply Agreements / Contracts.

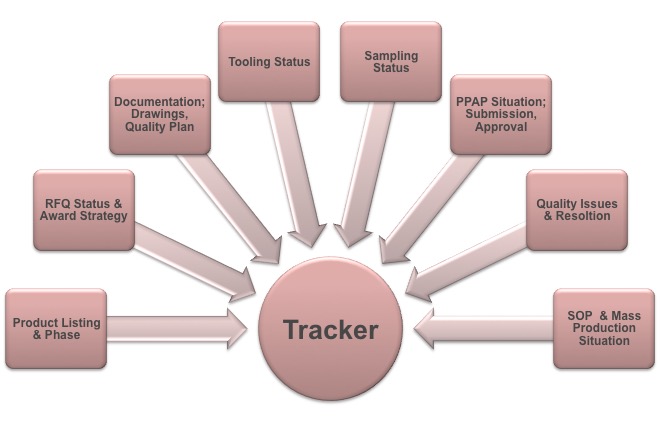

STC ensures a thorough control of its projects through the use of a Tracker that it shares with the client team as the principle means of communication. All the data about the project status is compiled in this document that is organised in such a way to generate real time reporting easily.

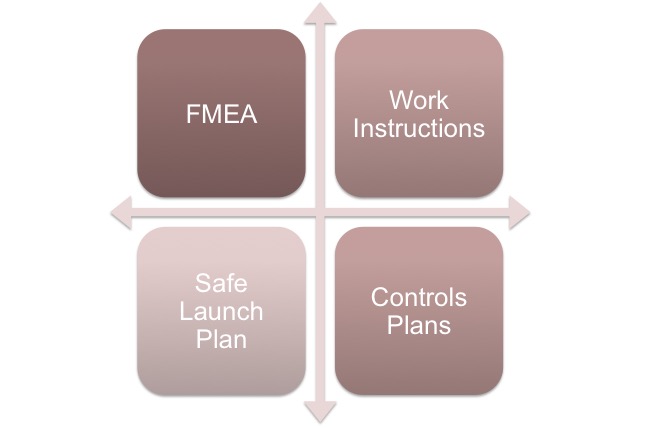

The quality planning strategy is built around a “back bone” with four key parts. As a key part of our process STC provides training to the supplier in these tools to ensure they are correctly prepared and used as they should be.

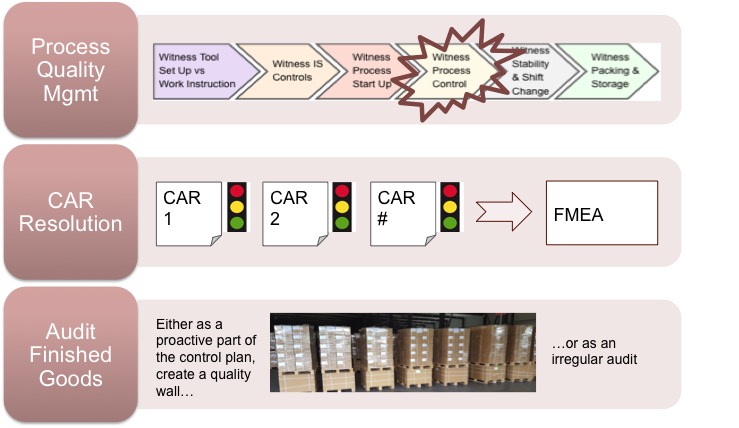

As the project moves into the SOP and mass production phase, STC is able to support the client further with the aim of continuous improvement and a strong focus on quality.

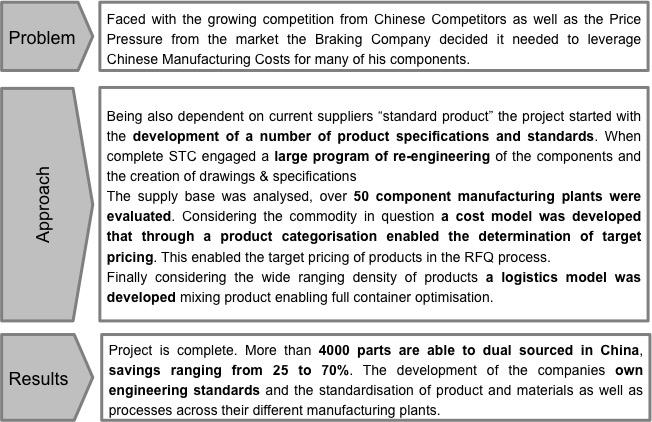

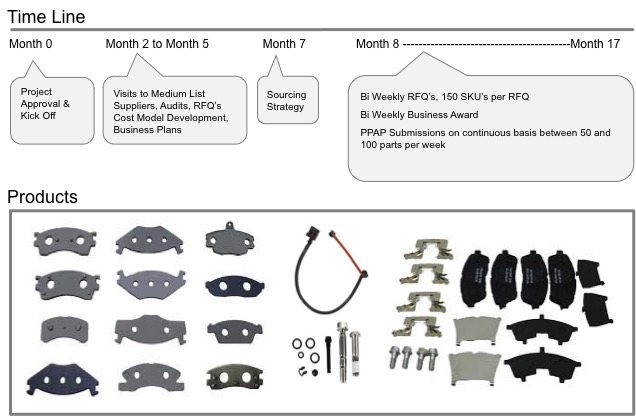

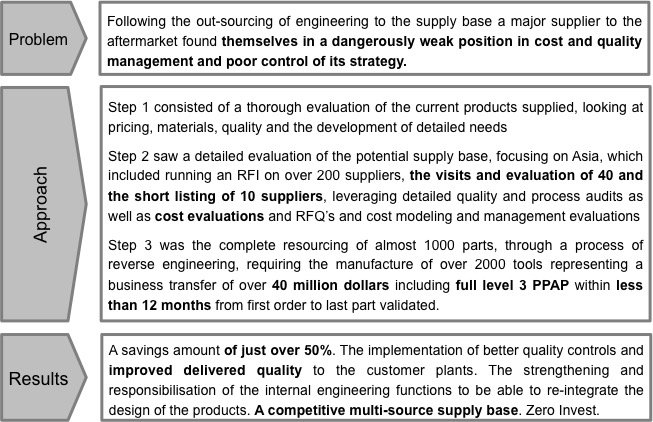

Case Study 1

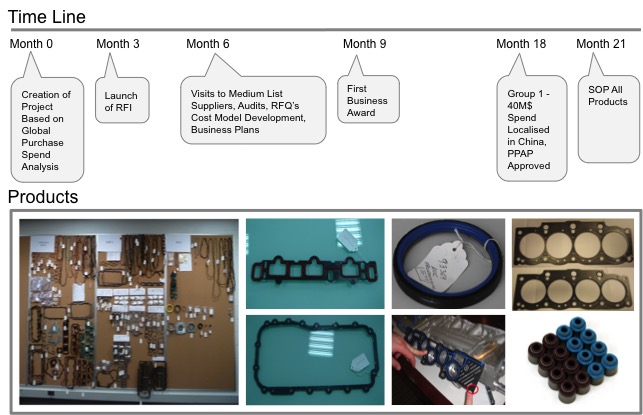

Case Study 2