Introduction

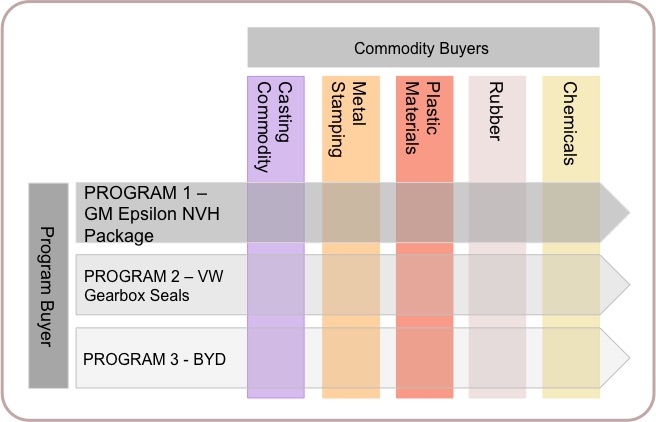

The recent and substantial growth realised by companies today, particularly in China, naturally or by acquisition, is causing them to look inwards more and more at their organisations and strategies. One such domain is purchasing. In particular companies that have made acquisitions in either similar or non related product lines or acquisitions internationally are now wishing to understand how they can leverage their spend to maximise their advantage.

In addition as these companies increase in sophistication the purchasing organisation is required to interface with the other functions; R&D, Quality, to name a few, at different times and on a wider range of topics.

The suppliers too are developing their world-wide footprint and forcing their customers to be better coordinated.

STC understands very well this problematic. The solution is not simply trying to do as the others, more do as you need to do. Therefore a “customised” solution is often necessary. Further, organisations are living things and as the business profile develops, geographically, product line wise, or other, the strategy and organisation needs to evolve.

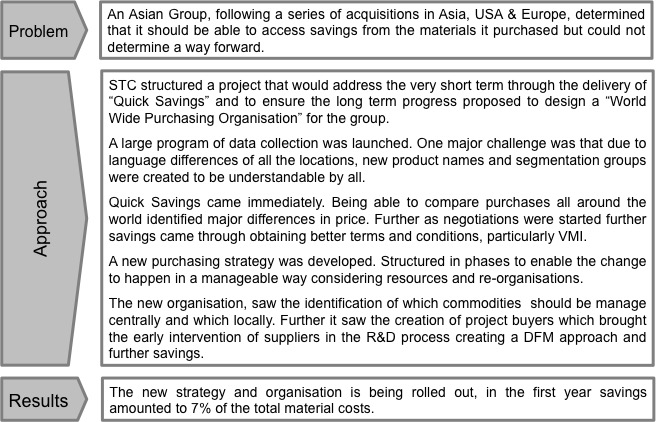

Process

The approach that STC uses to structure these projects follows four phases.

Some of the key topics that would be addressed in a Purchase Strategy & Organisation Project include:

- Data Gathering & Segmentation

- Commodity and Project Buyers

- Resource Demands

- Centralised and Non Centralised Purchasing

- Productivity – Process & Technical

- Reverse Marketing

- Roadmaps for Progress

Data Gathering & Segmentation

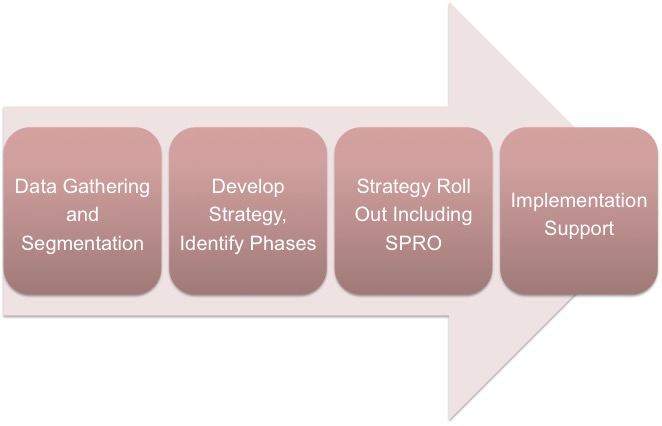

This is the starting point. STC gathers the purchase data from all the activities of the client group. It is consolidated then built into segmentation. These segments are carefully selected so that they can be later exploited. The segments are also multi-dimensional; product, process, material and in some cases function.

STC not only looks at the direct purchases, like plastics, rubber, metals, components, but also at the indirect purchases that could include; machines & equipment, maintenance, supplies, general expenses.

Importantly STC takes care to make sure that all the sites have an understanding of each other and use the same terms that ensure that they are able to understand one another.

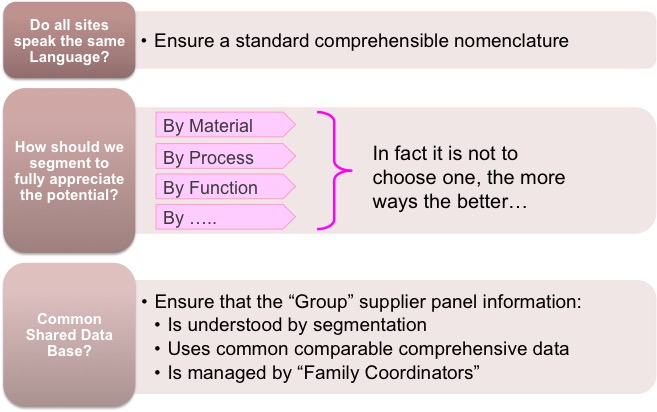

Commodity and Project Buyers

A key challenge clients face is how to support the programs in R&D and at the same time ensure a coordinated approach in front of the suppliers. STC carefully understands the value that can be created through the early involvement of purchasing in the development process looking at the same time at the capability of the suppliers to also bring appropriate support.

Resource Demands

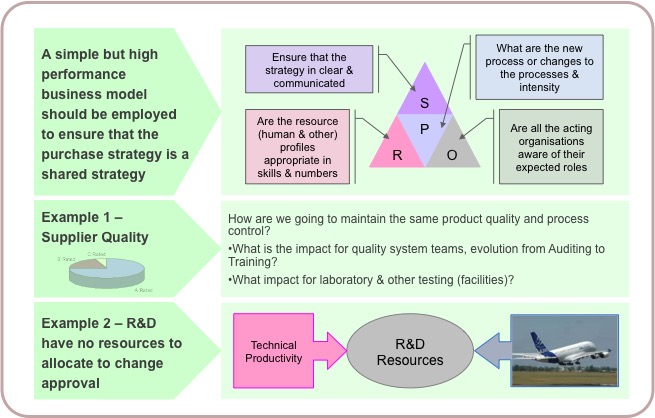

As the purchasing function becomes more integrated into the company, with wider responsibilities, including for example supplier quality and productivity, so the demands on the functions resources and capabilities increases. STC develop an understanding of the strategies of the key interfacing functions and ensure alignment. This alignment is then translated into processes, which drives organisational and resource needs.

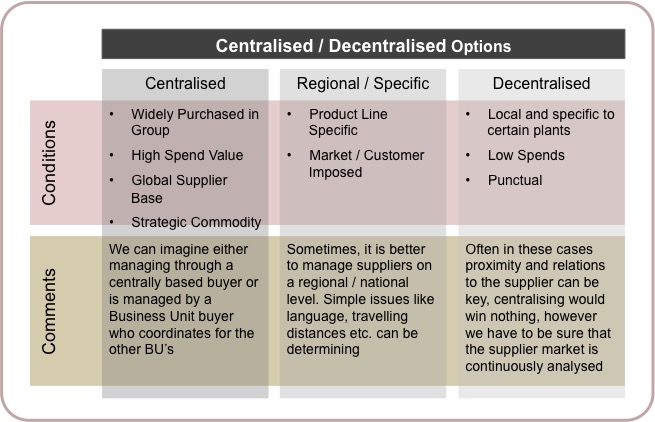

Centralised and Non Centralised Purchasing

There is not one better than another. There is not a company where one or the other should be “blanket” applied. There is a need that for each commodity, for each geographical location or product line the subject is studied individually.

STC looks at how each commodity will be managed from the bottom up. Meaning that for some commodities STC will propose a central purchasing organisation and for another, either a partial or fully decentralised organisation. These initial organisation decisions will form the basis for the rest of the organisation, however as the project progresses, they may be modified to accommodate other important aspects like supplier integration.

Productivity – Process & Technical

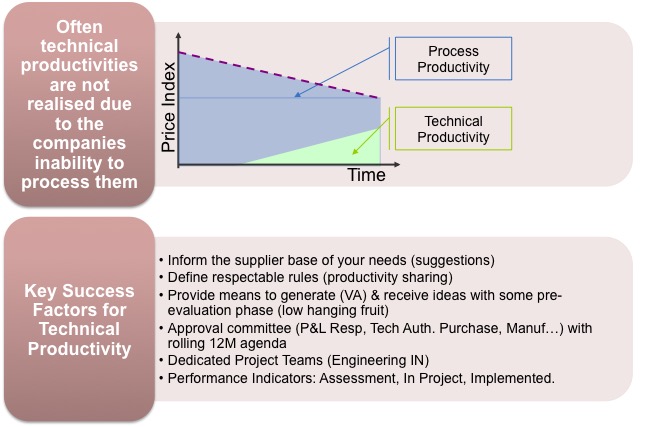

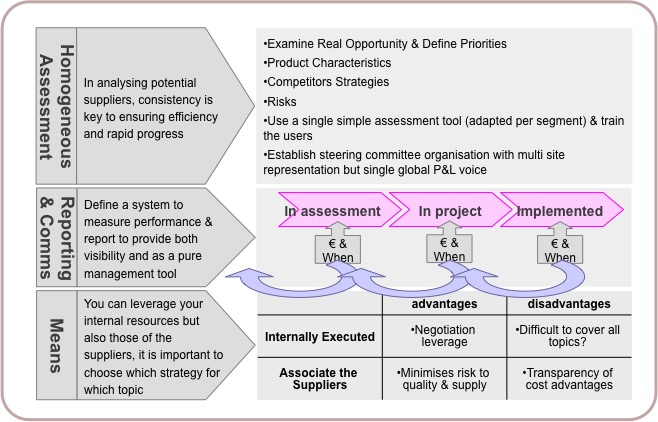

With materials and purchased parts representing such a high proportion of the sales value it is also a major opportunity for savings through productivity. STC identifies the potential, based on a long experience, and will dimension the organisation appropriately to be able to manage.

As a major strategic axis, the whole company needs to be aligned and the organisations of the other functions too. The productivity drivers can be both process and technical. The suppliers can be a major source of ideas and processes are required to solicit, assess and implement the changes.

Reverse Marketing

The combination of technology, materials development, processes and continuous improvements in the supply base means that companies need to constantly evaluate their suppliers to understand if they are the best in class. New suppliers may present themselves, but it is necessary that the purchasing function is pro-active in knowing the full supplier base and selecting the most appropriate.

Roadmaps for Progress

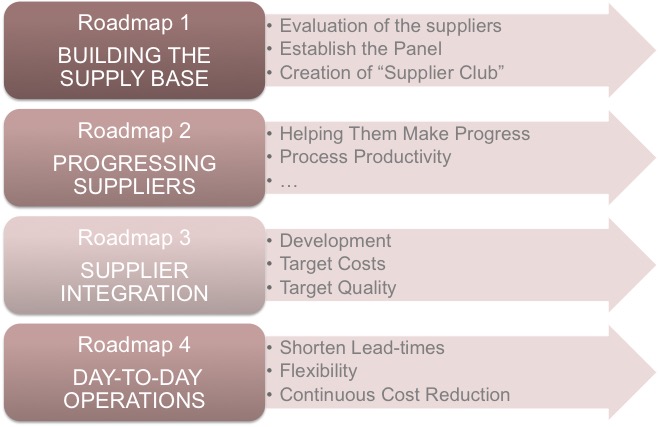

The Supply Base needs to be developed. This development is structured through a series of Road Maps. Effectively the suppliers who progress the most along these “Roads” will become the long-term partners to the company.

For example, the “Supplier Club”, The concept of the “Supplier Club” is to form a sub panel of suppliers that will have to attain a certain performance linked to aspects of “Quality, Cost, Delivery, Engineering and Management”. It will be limited in number. It will be difficult to enter and only the very best suppliers that will be able to support the customer in their growth will be permitted. In exchange for this performance these suppliers will be systematically included in all RFQ’s and invited to participate in the early conception of new products.

Roll Out – SPRO

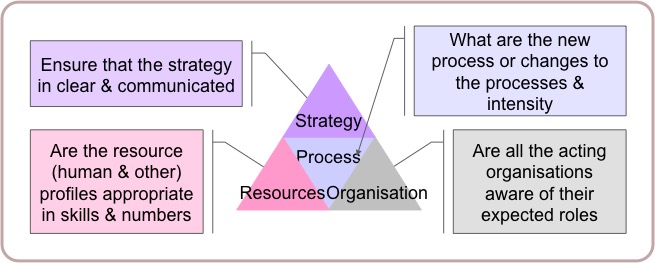

As the new strategy takes from it needs to be implemented. To facilitate this implementation STC uses its SPRO approach. New Processes will be required either within the purchasing function or between purchasing and other functions. A supporting Organisation and Resources will also be necessary.

Case Study