Introduction

Any optimisation of Logistics Operations has to consider the whole supply chain, door to door, to ensure that in the end the problem is not just moved from one place to another. Also any solution should be one that remains flexible and will enable the evolution of the business in the future. STC takes particular care of these points in its data gathering and design phases.

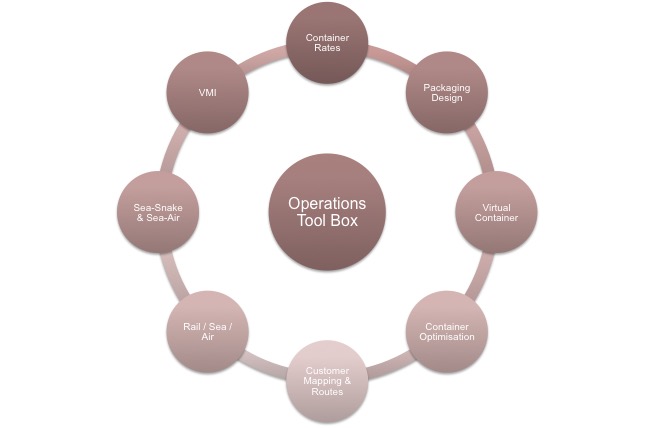

STC Tool Box

In the optimisation of the Logistics STC has developed and refined a number of tools. These tools may be employed individually, but often together. They may also be used as part of a far larger project of change in strategy as an element to deliver quick savings as well as those longer-term.

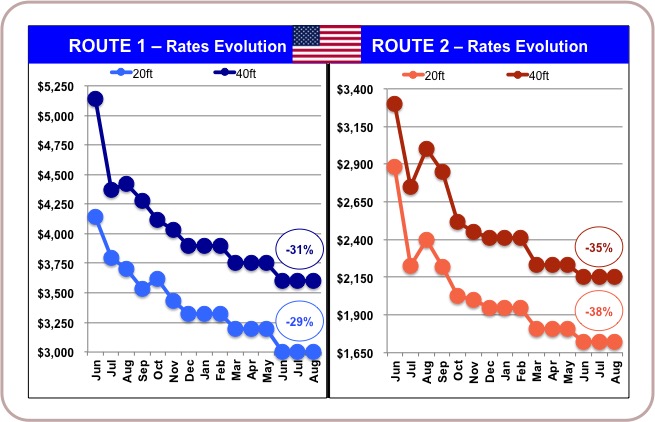

Container Rates

STC has developed a strong understanding of the freight forwarding procurement domain. This understanding covers aspects like; the forwarders themselves, trends and cycles, routes and options. STC can evaluate the current pricing and design and manage on behalf of the client the RFQ strategy for the freight forwarding service. Our “independence”; no history nor obligations to these companies ensures fairness. Secondly because the 3PL’s recognise that having to work through a third party like STC means that competitively it is a key driver. The rest is filtered out.

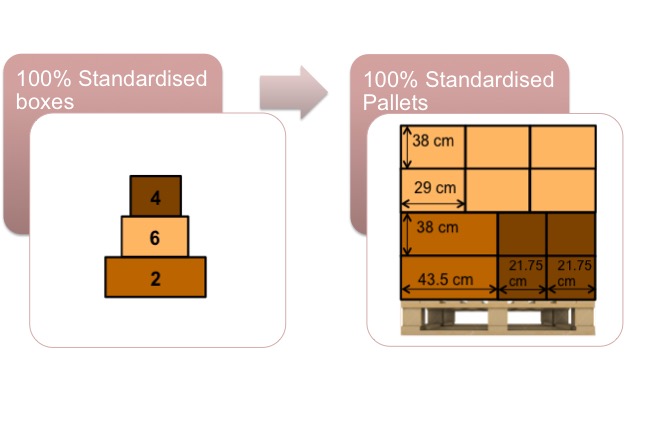

Packaging Design

From the simple but laborious task of ensuring all packaging data is correct, through to the complete re-design of all packing to enable “inter-stack-ability” of multiple density products. STC bring concrete recommendations and re-designs of the packaging for this important step to facilitate container optimisation.

Virtual Container

A key obstacle in such products is the on time coordination of all products destined for the same container. Here STC use a combination of the Virtual Container. This operation could be supported by specific software that collects all the shipping orders and would translate them into a most optimised containers packing list.

Container Optimisation

The maximum optimisation comes once the packaging design has been corrected and is enabled through the virtual container. Key in the optimisation is the segmentation of products; A,B,C, that allows 80% of the shipments to be combined together into regular optimised containers, thus standardising the process and simplifying the tasks. This liberates resources to focus on the more difficult problems. This automation can be further enhanced through the shipping in the form of the “Sea-Snake”.

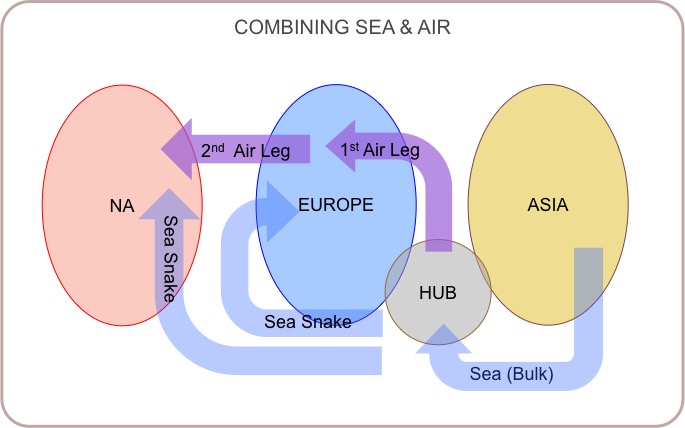

Rail / Sea / Air

Whether shipping from Europe to Asia, or Asia to Europe the three principle means should always be evaluated, but not in absolute terms but looking at the whole cost or whole savings opportunity. Longer lead-times could mean more safety stock. Safety stock often carries a premium cost to manufacture and consumes cash. Faster time to production will bring the savings, associated with such projects, faster too.

Further circumstances dictate that the costs of each are constantly moving therefore require constant evaluation. Combining different modes of transport, particularly sea-air can also be an interesting solution.

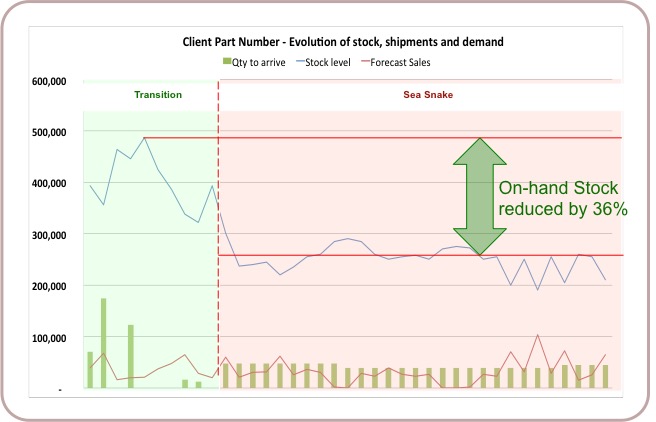

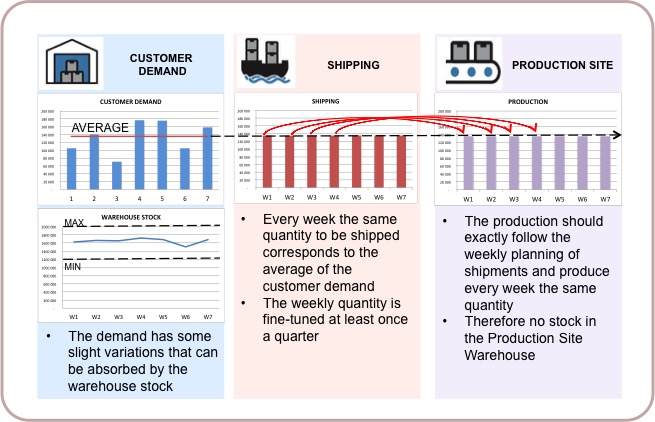

Sea Snake

The sea snake is designed to complement the container optimisation. It brings further benefits; reliability of delivery, reduced safety stocks and helps the factory capacity planning. Starting from the Products segmentation it identifies how to regularly ship the same volume, leveraging safety stocks at appropriate levels to manage customer variation. These regular shipments and regular deliveries provide confidence to minimise safety stocks thus saving cash. With regular shipments the factories can align with regular production allowing better planning and better machine utilisation.

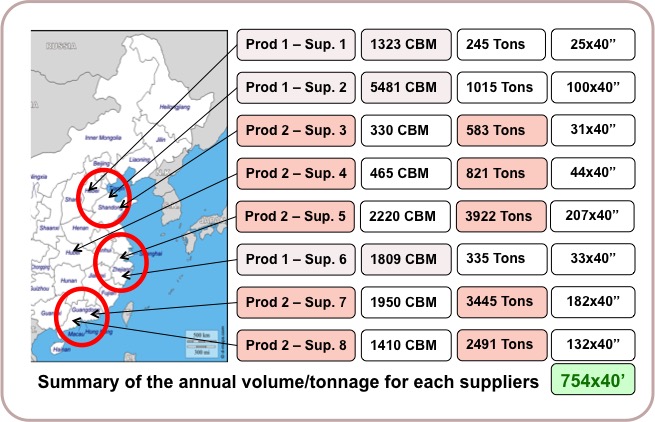

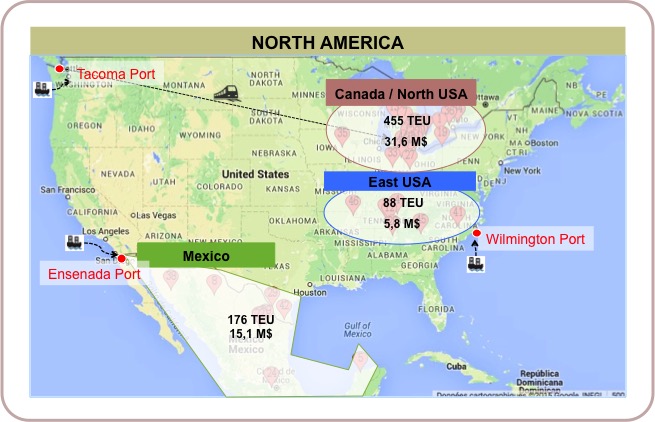

Customer Mapping & Routes

Linked to “Container Rates”, and the RFQ process and the understanding of the breakdown of the forwarding costs, STC will determine the best routes possible. The location of suppliers, ability to consolidate and optimise containers, port to port routes and then distribution costs; road / rail, are all put into the balance and the optimal route determined. In this domain, what is key are the business dynamics to ensure that as these evolve the routes are constantly evaluated to be optimum.

Processes and KPI’s

As these tools are implemented STC shall in parallel work with the clients team to formalise them as new processes. Further STC provides training to the client team in their use. STC will also provide “after-project” coaching, typically in the form of a monthly steering committee where the clients management will be able to see the effectiveness of these changes supported by carefully designed KPI’s (Key Performance Indicators).

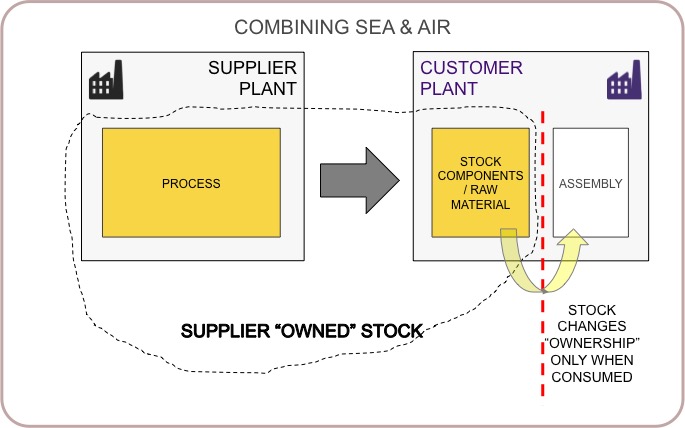

VMI

Vendor Managed Inventory is a “Quick Win” tool to bring impact to both the P&L and the cash needs. If volumes and business value are substantial, the customer should integrate into his negotiation strategy the creation of a VMI. The advantage is to obtain better purchase conditions and simplification of the supply management tasks.

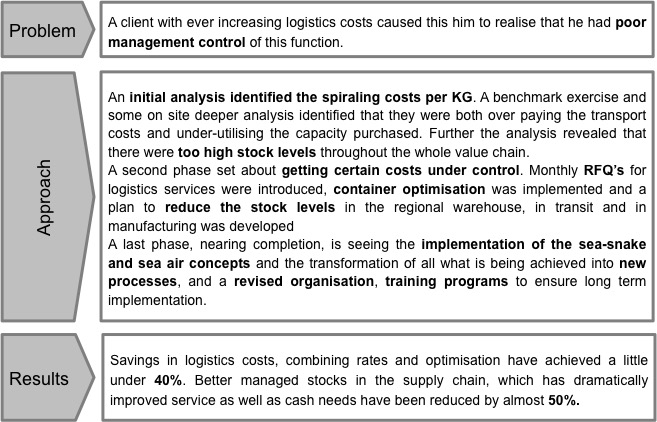

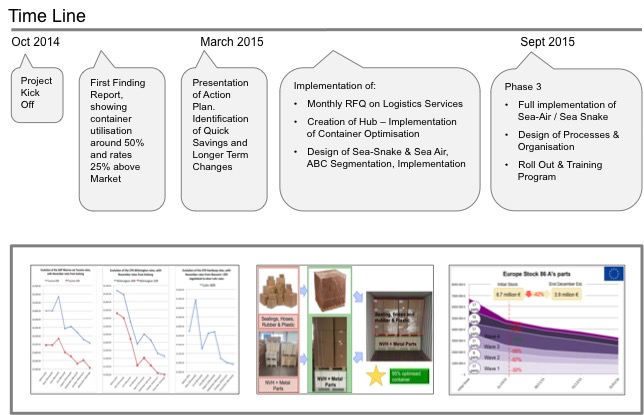

Case Study